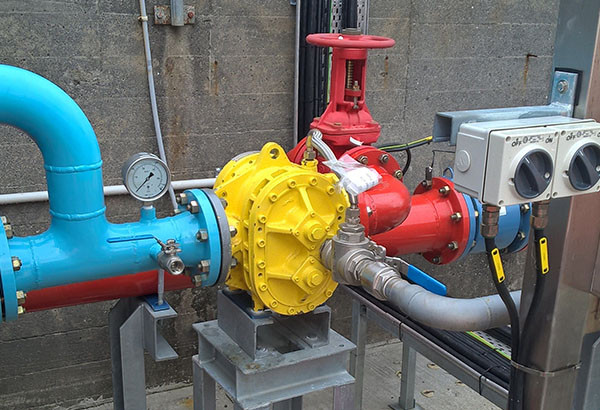

After uncovering the problems faced by our client, we immediately recommended the ‘Turbinator’ – our industry-recognised Knowsley SK foam mixing system.

It’s the go-to choice for a growing number of our end users and consultants, thanks to a wide variety of features and multiple applications. We knew its nominal footprint would be ideal for the smaller space our client had on-site, and its ability to mix foam accurately is excellent. We were also able to offer 3 different sizes to accommodate the specific flow rates required, from 500 – 12000 L/pm.

Fit-for-purpose solution

With a quick and simple installation by our local partners, we were able to provide a solid, effective, ‘fit-for-purpose’ firefighting solution.

The strong materials and excellent functionality of the Turbinator make it highly capable in both on and off shore environments. It provides our client with absolute peace of mind in any emergency situation, even in a hazardous area like a refinery.