APPROACH

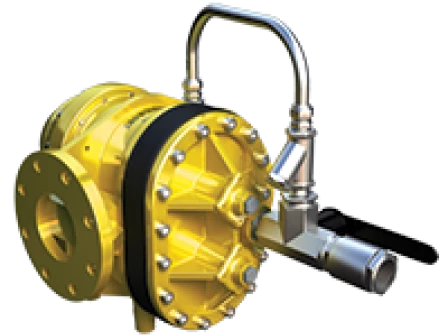

Knowsley SK designed, manufactured, delivered and commissioned a Turbinator foam skid to replace the existing bladder tank and balanced pressure proportioner. The Turbinator system was provided in a skid package with one tie in/out flange which minimised changeover time offshore and offered the following advantages over the bladder tank system:

- Very low maintenance with no expensive testing regimes.

- Foam System can be topped up easily by non-skilled personnel.

- Can be tested with training foam or water from an external source.

- Foam can be accurately proportioned over varying firewater inlet pressures.