FOAM CONCENTRATE

The critical component of a foam system is the foam concentrate, which is mixed with water in a predetermined percentage, as defined by NFPA 11 and other industry standards to create a foam solution.

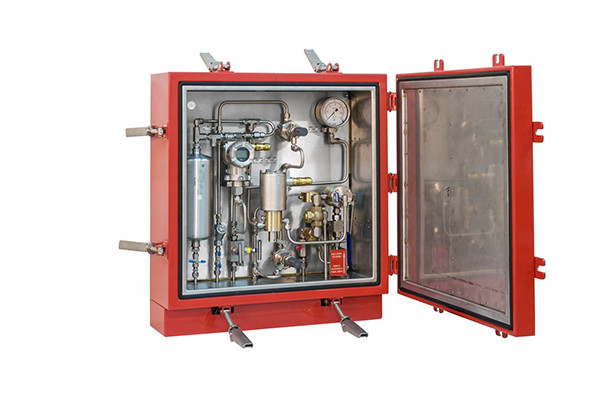

With several methods of mixing (proportioning) the foam concentrate, Knowsley SK has all devices available. This includes foam inductors, balanced pressure proportioners, bladder tanks and of course the Knowsley Turbinator or Smartmix systems.

FOAM MIXING DEVICE

We design the complete system around the type of foam mixing device selected, so that we can ensure correct operation and give you the preferred level of control and automation.

Learn more about the different types of foam proportioning methods

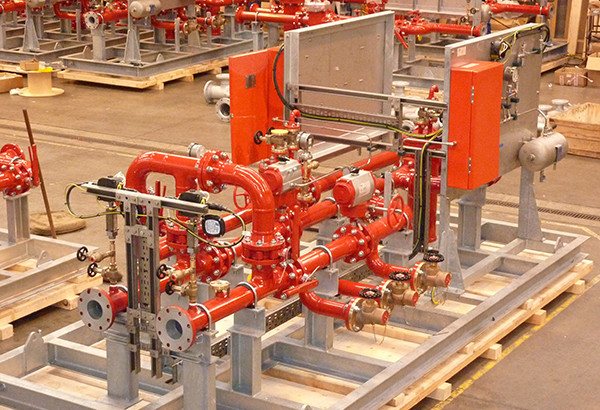

BUILD SKIDS

We specialise in building this equipment into skid assemblies so that we can provide you with ease of installation, hook up to all critical services (such as firewater and E&I) and the confidence of knowing that the full package will be fully function-tested at our factory.

As part of the initial design evaluation by our specialist engineers, we will determine the optimum type of foam proportioner to suit each application and then customise the skid assembly to suit site conditions.

OUR RECOMMENDATION

Consider the following areas