A gear pump can handle fluids that are too viscous for a centrifugal or piston pump. The pumping action of a gear pump is very controllable and mathematical: The output of a gear foam pump is independent of discharge pressure.

Since a gear pump doesn’t have to generate centrifugal force, it can be run at a much lower speed. This makes it smoother, more precise, quiet and controllable.

Gear pumps are self-priming, which can be a huge benefit as that they poses a huge fluid suction lift. Their discharge pressure can be very high, dependent upon a number of factors. A gear foam pump dos not have a BEP or best efficiency point; they are consistently efficient.

POSITIVE DISPLACEMENT PUMP

The positive displacement pump provides and constant flow depending on demand at affixed speed, despite changes in the counter pressure.

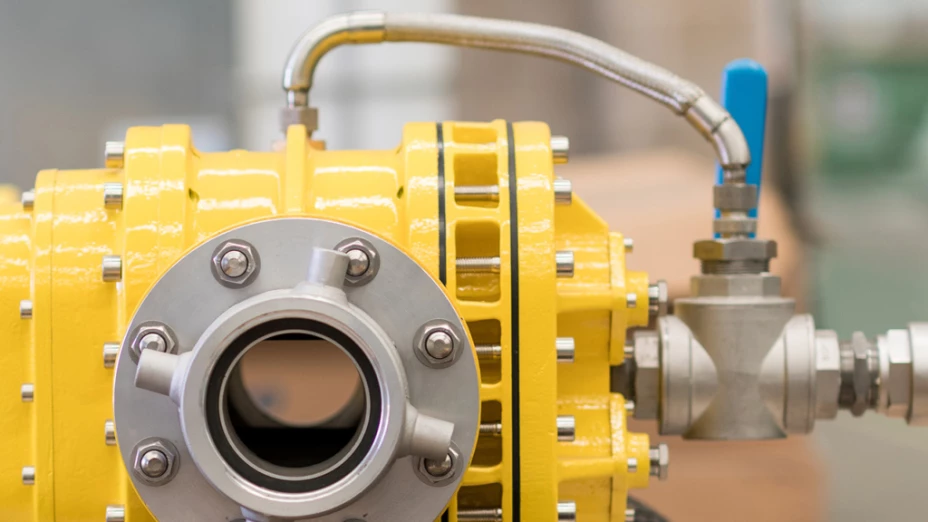

By using an gear Pump combined with a positive displacement Pump, Knowsley has developed the Turbinator, an innovative water Driven Foam portioner that provides simplicity housed in one single body.

THE TURBINATOR

The Turbinator is a positive displacement foam proportioning pump designed for Fixed and Mobile applications. The unit is driven by a special volumetric water motor which is directly coupled to a precision gear foam pump. Because both parts of the Turbinator are positive displacement devices, the ratio of foam concentrate to firewater is fixed over the full operating range. This makes the Turbinator the ideal proportioning technology for systems with different flows, such as multi-legged deluge systems, sprinkler systems and mobile large incident equipment.

The Turbinator unit does not require setting up or on-site adjustment – the proportioning rate is achieved at any flow rate and pressure within the operating range.