Deluge skids and systems are used for a wide range of fire protection risks including hazardous process plants, cooling of critical equipment, cooling of storage tanks or vapour mitigation.

KEY COMPONENTS

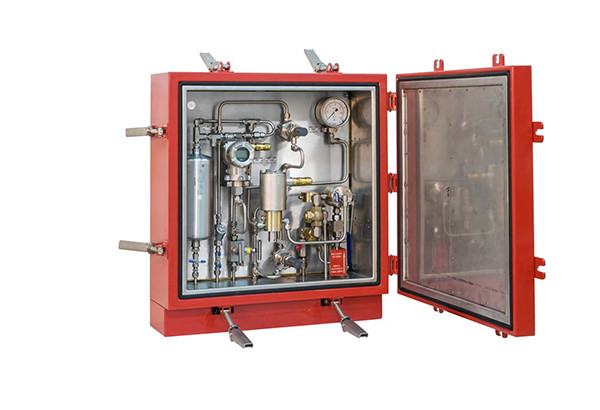

The key components of deluge systems are defined by NFPA 15 to ensure correct operation and testing of the main deluge control valve. As a minimum, they include the deluge control valve itself, upstream/downstream isolation valves and a test/drain valve to enable full system testing. Supervisory trim may also be required, to allow electrical or pneumatic release of the deluge valve and permit full system monitoring.

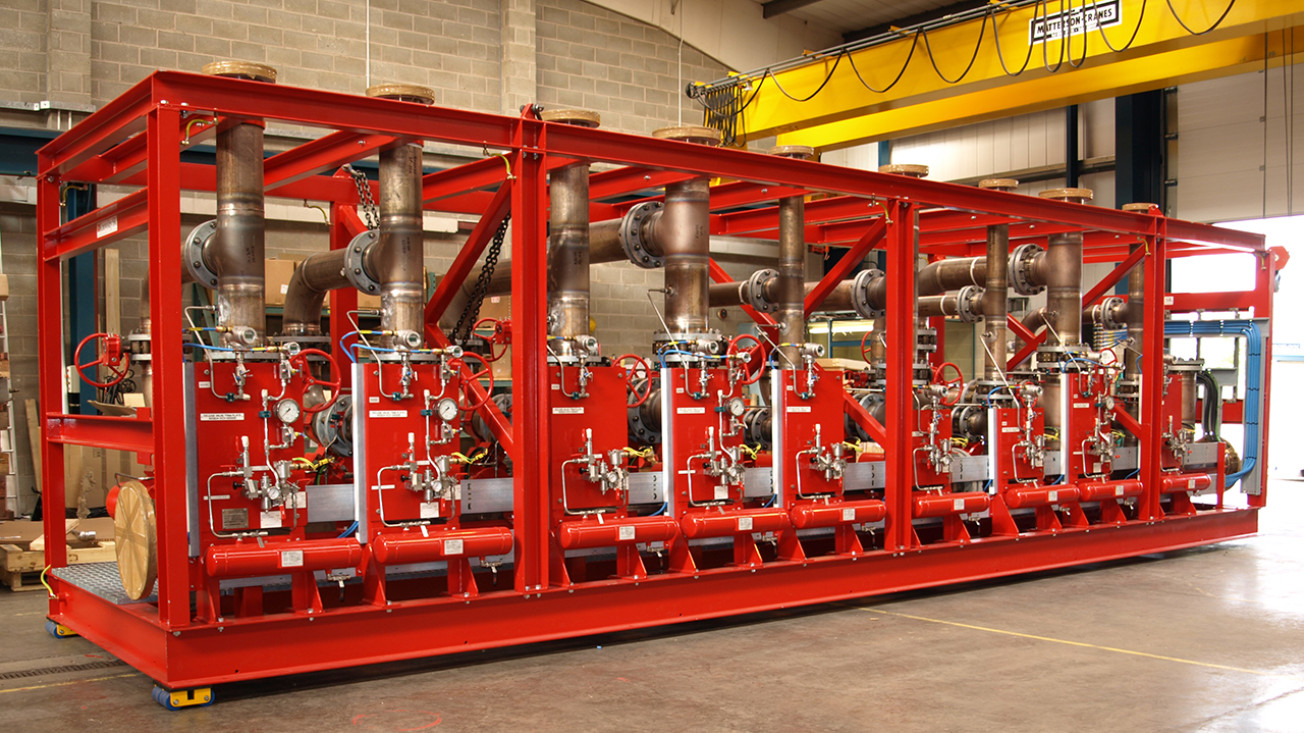

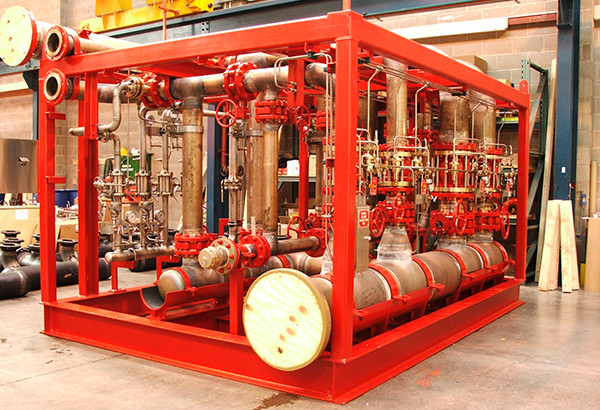

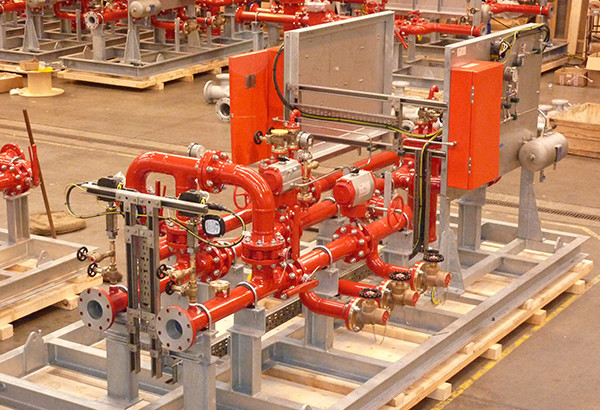

MODULAR DELUGE SKID PACKAGES

At Knowsley SK, we specialise in building this equipment into modular deluge skid packages, so that we can provide ease of installation and hook up to all critical services – like firewater and E&I.

We give you the confidence that your full package has been fully function-tested at our factory.

Deluge skids are generally bespoke, designed and installed in order to meet the specific conditions of a site or a project.

OUR RECOMMENDATION

Consider the following areas.

Deluge valves

Deluge valves are control valves which are listed and approved for deluge service and allow remote operation and control. They are available in a range of types and sizes to meet the flowrate requirements of the system. However, other types of control valve such as actuated butterfly valves may also be used, as long as they are acceptable to the authority having jurisdiction.

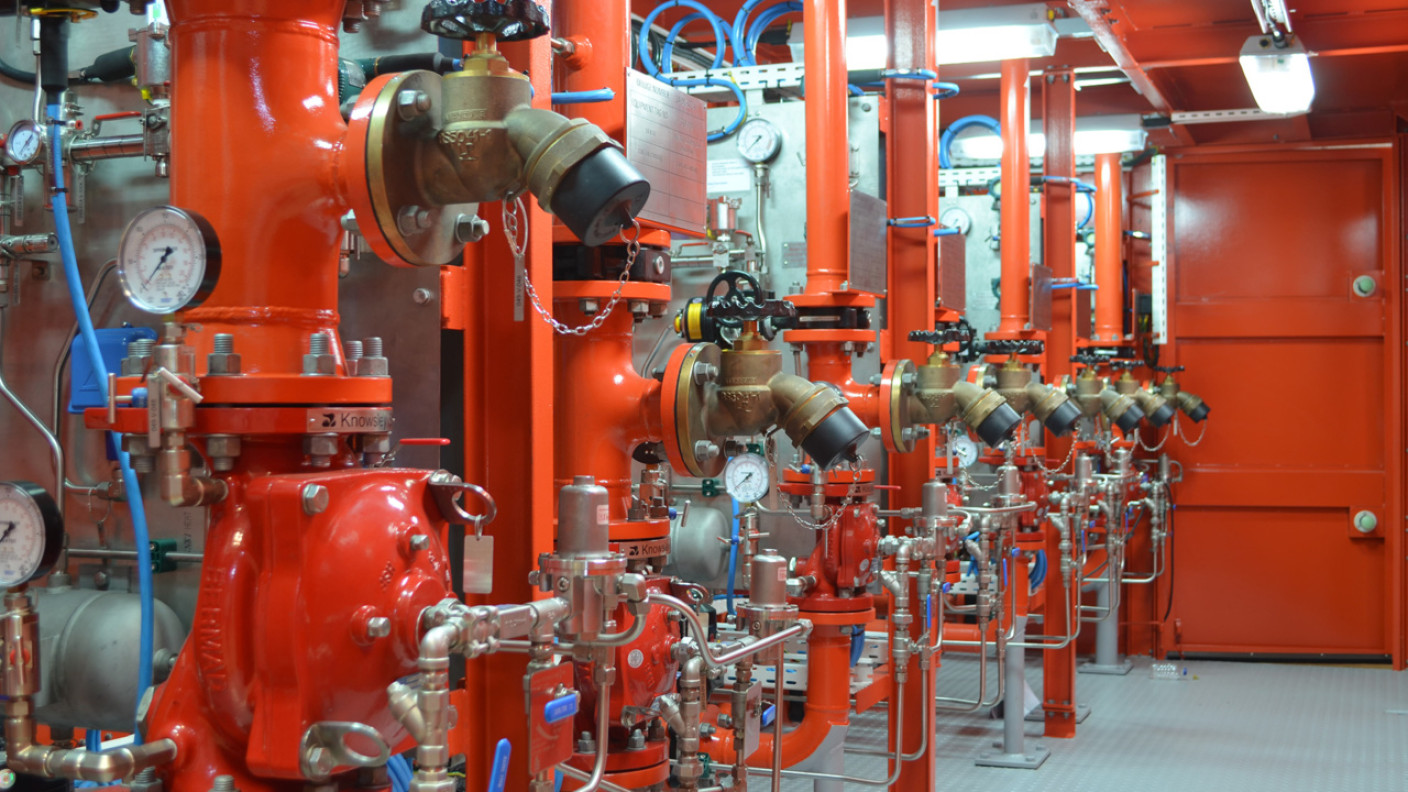

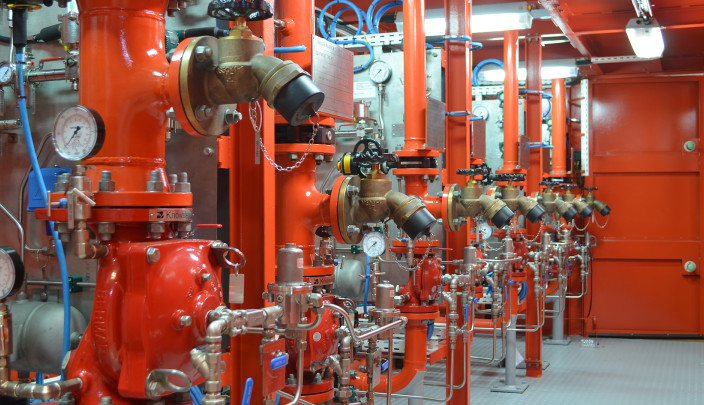

Release trim options

Release trim options can vary from the simplest system with pressure gauges, solenoid valves and water gongs, to the very high specification requirements seen on offshore systems which utilise pressure transmitters and dual electrical circuits.

Options for materials

Options for materials will generally be chosen with respect to the firewater type, but they should also consider environmental conditions. Different requirements will need to be made for the +50°C heat of the Middle East or the -50°C cold climates of the Caspian region. The skid itself can be fully enclosed and insulated as necessary.

Skid piping configuration

The skid piping configuration will be designed to match the tie-in locations preferred by customers and can additionally include system bypasses and a provision for full flow testing.

The end result can be a very complicated modular package which must be correctly designed to ensure full operation, and of course to allow for human factors and ergonomics.

At Knowsley SK, our team of experts has many years of experience in the design of deluge skids – for both simple and complex systems.