The result of this new requirement was that when applied to the 2 1/2” (DN65) size valves all manufacturers were de-listed from the FM approvals guide and the scramble was on to find an acceptable solution.

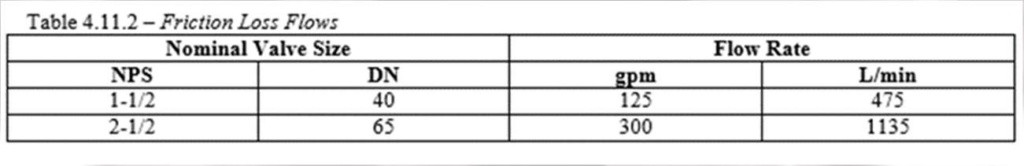

Specifications in industrial firefighting state valves should be approved (preferably FM or LPCB) and be capable of flow rates up to 946 l/min (250 GPM) or even up to 1135 l/min (300 GPM) depending on each customer’s specific application.

KNOWSLEY SK RESPONSE

The Knowsley response was to take the toughest route and obtain approval of our 2 1/2” (DN65) valves. This was due to the high flow rate requirement and the need to ensure that the fluid velocity through the valve was at limits we considered acceptable.

Were other solutions possible? A simpler route to reduce the valve outlet size and obtain approval with a reduced bore size of 1 1/2” (DN 40) was possible but in our evaluation, we considered the total operating range of the valve; and the resultant high water velocity at operational flowrates which at 946 l/min would be approximately 14m/s (50 km/h) through a 1 1/2” bore.

For Knowsley SK Ltd only 2 1/2” bore size was acceptable where velocity would be below 6m/s which is the goal in firefighting systems.

We are proud to confirm that we maintain FM Approval for the Hosesafe PRV at 2 1/2” DN65

PRV’s are also covered under BS5041-1:1987: Fire hydrant systems equipment – Specification for landing valves and wet risers. This states a minimum water flow rate through the valve of no less than 8.5L/s (510 l/min) and an outlet pressure of no less than 4 bar when the inlet pressure is 4.7 bar

We are proud to confirm that we maintain BRE LPCB Approval for the Hosesafe PRV at 2 1/2” DN65

At Knowsley SK, fire safety and the protection of people, assets and the environment are our number one priority and we will never compromise on those values.