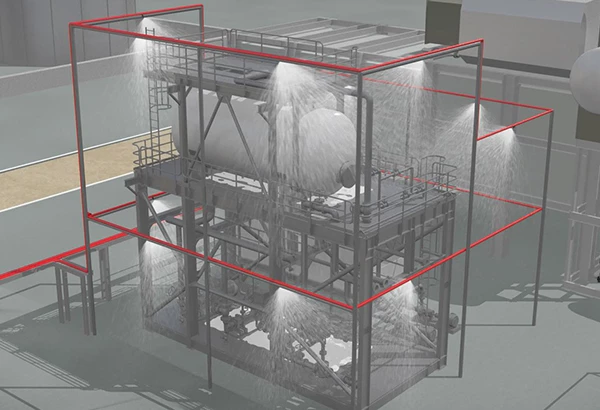

Fixed systems are ideally suited to Oil, Gas, Petrochem and Tank Storage sites, where an immediate foam application can be delivered via the press of a button, rather than calling on the emergency services. Control the situation safely – before it has time to escalate – by applying foam quickly to any flammable product spill or fire.

The Turbinator Fixed Foam Skid can be utilised to feed many end-of-line foam delivery devices, such as:

- Storage tank & bund foam pourers

- Jetty remote control monitors

- Process equipment foam deluge